End-to-End Digitization. Real-Time Visibility. Tier-1 Performance

40+ Businesses

110+ Warehouses

4000+ User

Revolutionize Your Warehouse with Intelligence

iStorePRO is a Tier-1 Warehousing Intelligence Platform engineered to digitally transform end-to-end warehouse operations across diverse industries. By seamlessly integrating advanced Warehouse Management Systems (WMS) with cutting-edge automation, iStorePRO empowers businesses to optimize efficiency, enhance accuracy, and drive agility throughout their supply chain.

25000+

Warehouses Transformed

3000+

Customers Streamlining Operations

Why iStorePRO?

Data analytics tools for real-time, data-driven decision-making

Smart Devices & IoT for enhanced operational efficiency

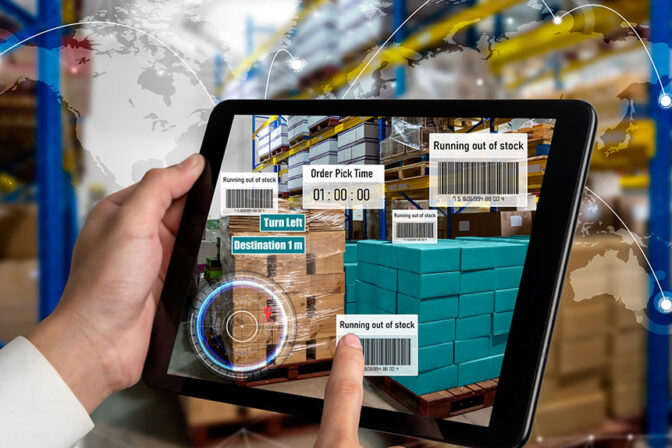

Augmented Reality (AR) for optimized warehouse navigation

Seamless Integration with Warehouse Automation to streamline logistics

Unlike traditional warehouse management systems, iStorePRO leverages an advanced Warehouse Intelligence Platform that is:

- Powered by industry-standard processes and best practices

- Optimized for global accessibility, ensuring consistent and efficient operations across locations

- Delivered through a subscription-based model for scalability and seamless integration

- Supported by expert consultancy for tailored solutions that align with business objectives

- Designed to standardize operations and scale effortlessly across geographies

- Equipped with multi-layered security and comprehensive data update trails

- Future-proof with zero risk of technology obsolescence

- Engineered to deliver a rapid return on investment (ROI)

Smart Devices Integration

iStorePRO integrated with smart devices like augmented reality (AR), smart glasses, and mobile/tablet applications enhances operational efficiency and accuracy.

Mobile/Tablet applications

Mobile/Tablet applications

AugmentedReality (AR)

AugmentedReality (AR)

Smart Glasses forVision Picking

Smart Glasses forVision Picking

RFID &Barcode

RFID &Barcode

QR codeIntegration

QR codeIntegration

Automated Guided Vehicle

Automated Guided Vehicle

Applicable Industries

Production Plants

Retail

Automotive

Energy

Freight Forwarding

Third Party Logistics

Fourth Party Logistics

FMCG

Our Clients